Tel.: +86 714 3703 589 E-mail: [email protected]

Ni Cr Mo steel characterized by high level harden-ability and toughness. Suitable for the fabrication of tools exposed to repeated impacts and strong pressure in service.

Product Details

Chemical composition

| C | Mn | Si | Cr | V | Mo | P | S |

| 0.40-0.50 | 0.15-0.45 | 0.10-0.40 | 1.20-1.50 | - | 0.15-0.35 | ≤0.03 | ≤0.03 |

Equivalent grades:

| DIN | W.Nr. | AFNOR | JIS | BS | SIAU | GB,YB |

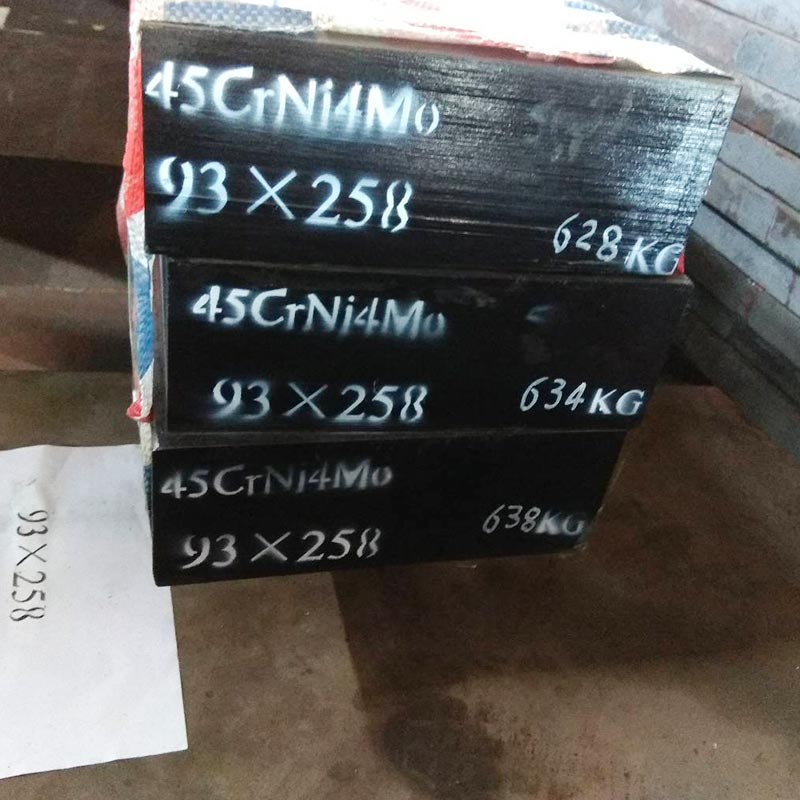

| X45NiCrMo4 | 1.2767 | Y35NCD16 | - | - | - | 45CrNi4Mo |

Application

Ni Cr Mo steel characterized by high level harden-ability and toughness. Suitable for the fabrication of tools exposed to repeated impacts and strong pressure in service. Treated for maximum hardness, it can also be used to construct cold work dies for cutlery, jewelry and plastic, anvils for hammers, rams and pile drivers dies and punches for horizontal forging machines rolls for hot work bending machines. It is advisable to use the blocks for dies treated at various hardness limits according to the etching depth complying with the indications given below.

Heat treatment:

Isothermal annealing:

- Heat to 880°C, hold at temperature for 1/2 h to 1 h;

- Furnace cooling to 610°Cand hold at temperature for at least 30 hours;

- Cool by 10°C/h to 580°C;

- Cooling in air.

Following isothermal annealing with sub-critical annealing, holding at temperature for 10-12 hours, maximum. Softening is obtained with HB<270

Stress relieving:

To be carried out after maching and before the final heat treatment.

- Heat to 630°C, hold for 4-6 hours;

- Furnace cooling to 300-350°C;

- Cooling in air.

Hardening:

- Initial preheating to 350-450°C;

- Second preheating to 650-750°C;

- Heat to hardening temperature in the range 850-880°C and hold at temperature;

- Accrording to the shape and dimensions of the tool, cooling in still or forced air, possibly, in oil or in salt bath at 450-500°C;

in the latter case, as soon as the temperature of the tool is even, continue cooling in air.

Quenched hardness:54-57 HRC.

Tempering:

In the range 550-630°C for 4-6 hours according to the hardness required, the dimensions of the parts and preating conditions, cooling in still air.

Before tempering, preheat the parts to 200-300°C.