Tel.: +86 714 3703 589 E-mail: [email protected]

Deep hardening response. It can be air hardened to full working hardness in section sizes up to 150mm. Good combination of toughness, hardness and wear resistance in hot. Resistance to softening and to cracking. Tools canbe water cooled. Following NADCA standard.

Product Details

Chemical Composition (%)

| Standard | Steel Grade | C | Si | Mn | P | S | Cr | Mo | V | W |

| DIN | 1.2343 | 0.36-0.42 | 0.90-1.20 | 0.30-0.50 | 0.030 | 0.030 | 4.80-5.80 | 1.10-1.40 | 0.25-0.50 | - |

| ASTM | H11 | 0.33-0.45 | 0.80-1.20 | 0.20-0.50 | 0.030 | 0.030 | 4.75-5.50 | 1.10-1.60 | 030-0.60 | - |

| GB | 4Cr5MoSiV | 0.33-0.43 | 0.80-1.20 | 0.20-.50 | 0.030 | 0.030 | 4.75-5.50 | 1.10-1.60 | 0.30-0.60 | - |

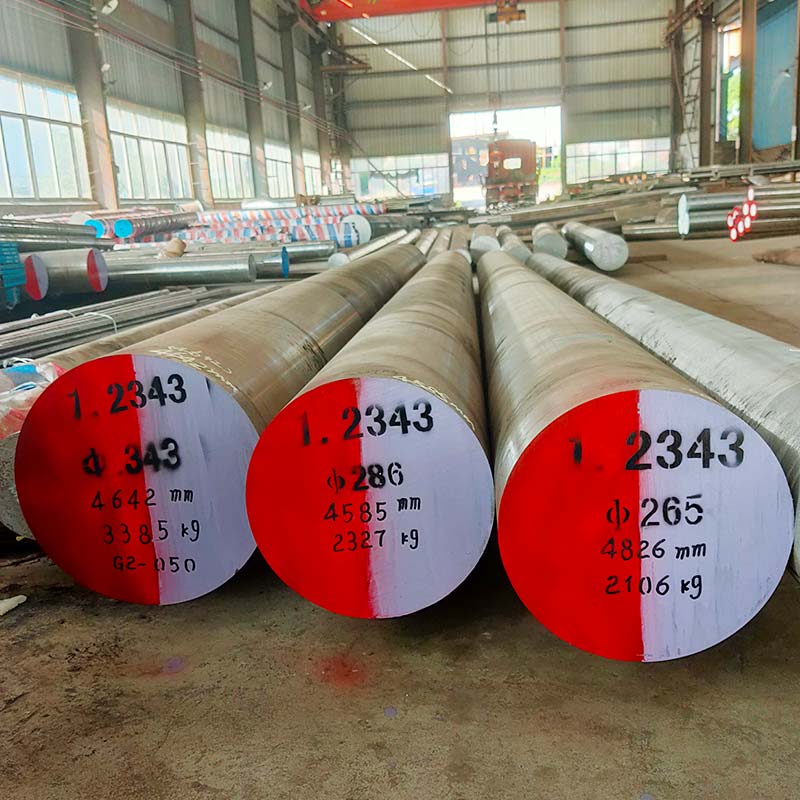

Specification

| Round bar | Diameter | Length | - |

| Forged round bar: φ50~450 | 2000~6000 | - | |

| Rolled round bar: φ10~80 | 2000~6000 | - | |

| Flat bar | Thickness(mm) | Width(mm) | Length(mm) |

| Forged plate: 20~300 | 50~710 | 2000~6000 | |

| Rolled plate: 10~65 | 155~610 | 2000~6000 |

| DIN | AISI | JIS | GB |

| 1.2343 | H11 | SKD6 | 4Cr5MoSiV |

Chemical Composition (DIN 17350)

| C | Si | Mn | P≤ | S≤ | Cr | Mo | V |

| 0.36 | 0.90 | 0.30 | 0.030 | 0.030 | 4.80 | 1.10 | 0.25 |

| 0.42 | 1.20 | 0.50 | 5.80 | 1.40 | 0.50 |

Steel Properties

Deep hardening response. It can be air hardened to full working hardness in section sizes up to 150mm. Good combination of toughness, hardness and wear resistance in hot. Resistance to softening and to cracking. Tools canbe water cooled. Following NADCA standard.

Applications

Tools with a broad range of working hardness up to tool working temp. 500 degree. Tools for hot forging of light metals. Pressure die casting tools, dies, mandrels, punchers, knives, and moulds.

Heat Treatment

| Soft Annealing(℃) | Cooling | Hardness(HB) | Hardening(℃) | In | Hardness(HRC) |

| 800-840 | Furnace | Max.229 | 1010-1040 | In air, oil, thermal bath 450-550℃ | 50-56 HRC |

| Tempering(℃) | 100 | 200 | 300 | 400 | 450 | 500 | 550 | 600 | 650 | 700 |

| HRC | 53 | 52 | 52 | 52 | 52 | 54 | 52 | 48 | 38 | 30 |

| N/mm2 | 1845 | 1790 | 1790 | 1790 | 1790 | 1910 | 1790 | 1570 | 1200 | 970 |