Tel.: +86 714 3703 589 E-mail: [email protected]

Low alloyed precipitation hardening steel, with good comprehensive mechanical properties, high hardenability, convenient heat treatment, small deformation after heat treatment, good polishability. This material also has good nitriding, electrical machining, welding and pattern marking performation.

Product Details

Chemical composition (%)

| Standard | Steel Grade | C | Si | Mn | P | S | Cu | Ni | Al | Mo |

| DAIDO | NAK80 | 0.06-0.20 | ≤0.35 | 1.40-1.70 | ≤0.030 | ≤0.030 | 0.80-1.20 | 2.80-3.40 | 0.70-1.30 | 0.20-0.50 |

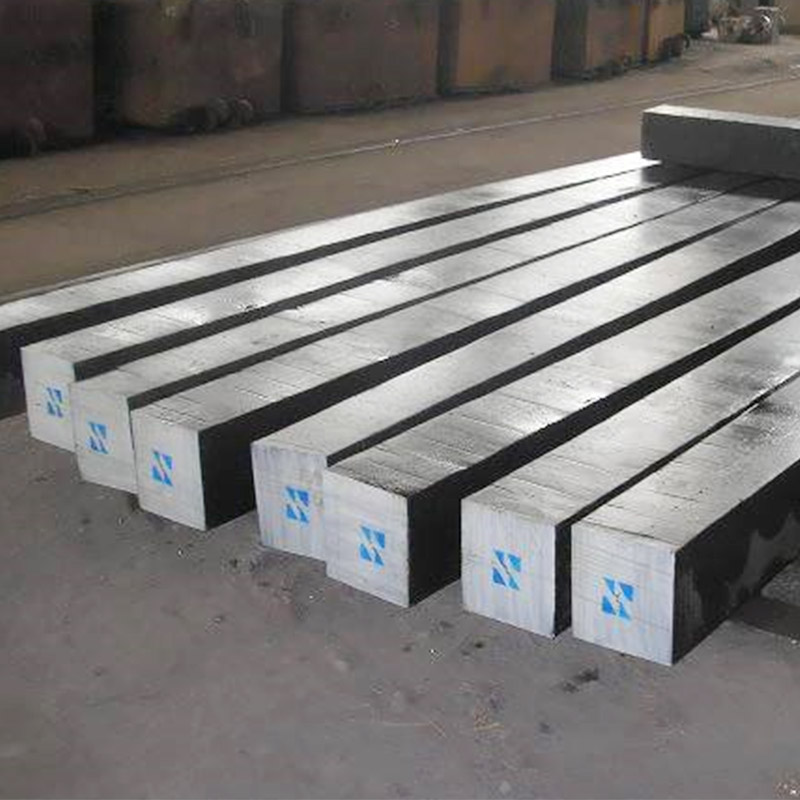

Specification

| Round bar | Diameter | Length | - |

| Forged round bar: φ50~450 | 2000~6000 | - | |

| Rolled round bar: φ10~80 | 2000~6000 | - | |

| Flat bar | Thickness(mm) | Width(mm) | Length(mm) |

| Forged plate: 20~300 | 50~710 | 2000~6000 | |

| Rolled plate: 10~65 | 155~610 | 2000~6000 |

Forging technique

| Charging temperature | Heat temperature | Initial forging temperature | Final forging temperature | Cooling |

| ≥800 | 1120-1160 | 1080-1120 | ≥850 | Air cooling |

Heat treatment technique

| Item | Annealing | Solution treatment | Aging |

| Temperature | 750-770 | 830-870 | 500-520 |

| Cooling | Furnace cooling | air cooling | air cooling |

| Hardness | ≤269HB | 32-34HRC | 37-43HRC |

Characteristic

Low alloyed precipitation hardening steel, with good comprehensive mechanical properties, high hardenability, convenient heat treatment, small deformation after heat treatment, good polishability. This material also has good nitriding, electrical machining, welding and pattern marking performation.

Application

Making high polishing plastic moulds, or moulds of household appliance which requires high surface condition.