Tel.: +86 714 3703 589 E-mail: [email protected]

With the advancement of the demand for plastic products and the expansion of application fields, higher and higher requirements are put forward for plastic molds, which promotes the continuous development of plastic molds, and at the same time, drives the rapid development of plastic mold steels, mainly in plastic molds The development of steel is accelerated, and the variety is increasing rapidly, but the current plastic mold materials are still mainly steel.

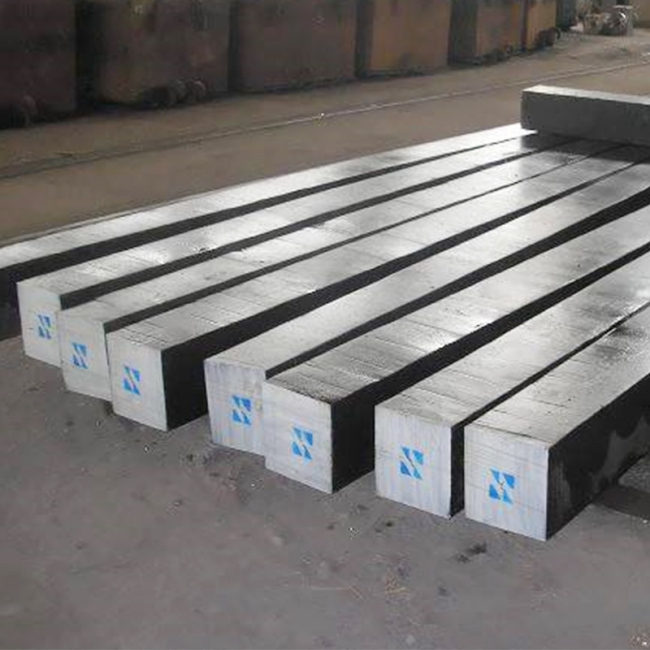

1. Plastic mold steel covers a wide range, from ordinary steel to special steel. This was more obvious in the early days of plastic molds, and now it has become more regular and advanced. Special steel has formed its own system. The chemical composition of die steel is basically the same as that of alloy tool steel, but its metallurgical quality is higher, and it is well processed, which is beneficial to heat treatment.

2. The performance requirements of plastic mold steel are strict, and heat treatment is difficult.

3. In order to avoid deformation of mold parts or other heat treatment problems during the strengthening and toughening process, it is common for mold steel to be supplied to the market in the form of pre-hardening.

4. Plastic products using petrochemical products as raw materials are corrosive to some extent, so corrosion-resistant steel is also used more.

5. With the application of pre-hardened steel and non-quenched and tempered steel, the machinability is also a characteristic of plastic mold steel.

In the past, there was no special plastic mold steel in our country. Generally, plastic molds are made of normalized 45 and 40Cr after quenching and tempering. Therefore, the mold hardness is low, the wear resistance is poor, the surface roughness value is high, and the appearance quality of processed plastic products is poor. Moreover, the service life of the mold is low; precision plastic molds and high-hardness plastic molds are made of alloy tool steels such as CrWMo, Cr12MoV, etc., which not only have poor machining performance, but also difficult to process complex cavities, and cannot solve the problem of heat treatment deformation. As a result, domestic research and development of steel for special plastic molds have been made, and certain progress has been made. my country has its own special mold steel series. Currently, there are two types of steel that have been included in national standards, namely 3Cr2Mo and 3Cr2MnNiMo. There are more than 20 types of industry standards, and more than ten new plastic mold steels have been promoted in production. The steel system for plastic molds in my country has been initially formed.

The above information is provided by the tool steel supplier.